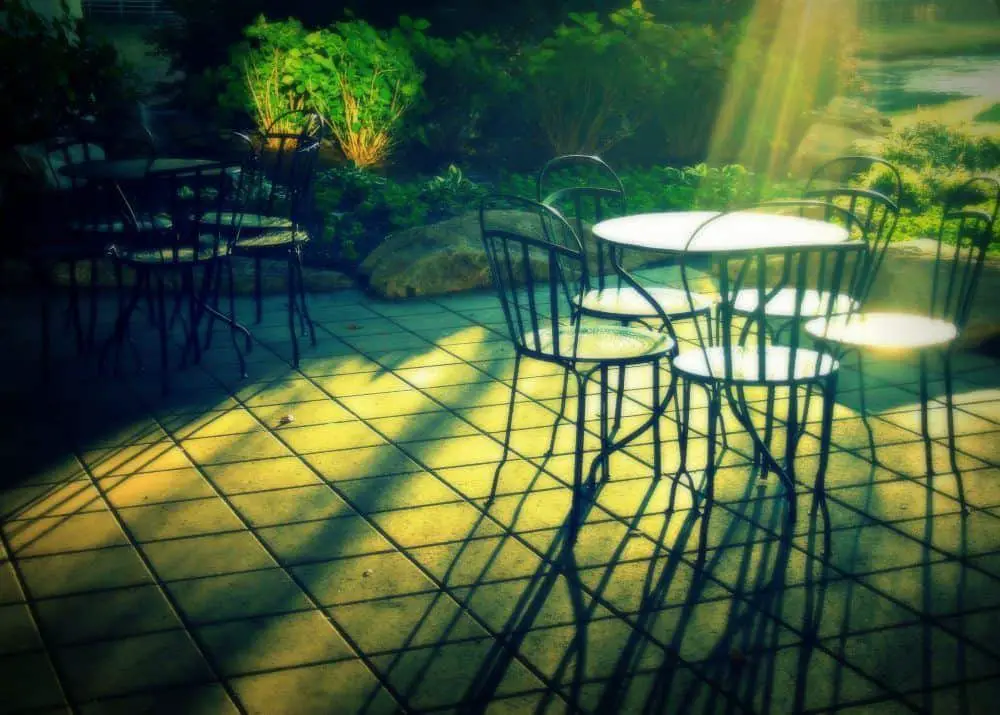

Concrete that is textured to look like brickwork, tile, slate, wood, or any other number of surfaces is known as stamped concrete and is usually seen on sidewalks, pool decks, and patios. In this article we're going to walk you through the benefits, and the procedures used to seal stamped concrete to help preserve it's appearance and increase it's longevity.

Using a concrete sealer will not only protect the look and feel of your stamped concrete but can even revive its original look. Sealing your stamped concrete comes with other benefits such as locking out moisture; minimizing thaw damage; preventing the fading of the color caused by ultraviolet rays; providing protection from stains, chemicals, and deicing salts; and in some cases, even improving the appearance. In addition, re-sealing also makes it easy to clean and maintain the surface and also adds sheen to it.

Table of Contents

Choosing the Right Sealer

For stamped concrete, the main type of concrete sealer used is either a solvent- or water-based acrylic. The reason for this is that acrylic sealers allow moisture in the slab to escape and hence, making the sealer breathable. it is also economical and easy to apply. They do not turn yellow easily and are resistant to ultraviolet rays.

With these types of concrete sealers there is lesser chance of the sealer turning milky or white and you can be assured that it will perform better when used outdoors compared to other water-based sealants.

But before you buy, you need to know if that particular product is indeed appropriate for your home project. These are the questions you should be asking yourself to help you decide:

Why Seal Stamped Concrete?

To the untrained eye, your stamped concrete surface may look fine, save for some wear and tear - but over time all concrete can and will degrade. Really, the answer is simply this — you need to protect your investment.

Sealing is recommended if your new concrete driveway has cured or whether it has been a few years since you put in the concrete. You can tell that it has been sealed due to its glossy sheen. If it looks faded and old, you may want to know how to reseal stamped concrete to make it look new again.

Your surface will be exposed to all kinds of elements such as leaves, dirt, fertilizer, pet urine, and chlorine salts. The right type of concrete sealer will keep these elements off, stop them from penetrating the surface, and prevent ugly stains. If your house is located in an area with colder climates, the chances of freeze-thaw damage will be reduced if the concrete is sealed. Freeze-thaw damage happens when the water that has been absorbed by the surface first freezes, and then expands, causing cracks in the surface that will need to be repaired with crack filler.

What the concrete sealant does in this case is stop the water from penetrating the surface, causing it to bead up. If you do not see beads on the concrete surface, you might want to seal your stamped concrete again. You also need to re-seal surfaces which see a lot of heavy traffic.

Sealing Stamped Concrete

One way to ensure your concrete always look great is to reseal it every few years. Normally, as a final step, contractors seal after installation. But we cannot stress enough that resealing concrete every few years is important. Here is a step-by-step guide on sealing (or resealing) stamped concrete and keep it in great condition for a longer period.

Clearing the Area

Before you seal the area, clear the area of junk and store them somewhere else in the meantime. Moving around these items while you seal the area can ruin the output of your work no matter how good the concrete sealer is.

Washing the Concrete Surface

Before you start putting the sealer on the stamped concrete, it needs to be cleaned thoroughly. It needs to be free of any contaminants such as spilled oil, grease, dirt, paint, or waxes before you seal the area.

You can use a garden or a power hose to clean the surface thoroughly and use a mild detergent and a brush to clean the dirt off from the corners. Make sure that all the soap is washed away. If you are using an industrial cleaning product, read the instructions on the label and follow them carefully.

Allowing It to Dry

After giving the concrete surface a thorough wash, it is important that you let it dry completely. This takes about 24 hours or more, depending on the weather condition. If you put concrete sealer on a wet or damp surface, a “blushing” effect occurs. This happens because moisture is trapped under the sealant, giving it a cloudy, undesirable look.

Applying Sealer to your Stamped Concrete

Before you seal the surface, you must divide the area into smaller parts. This will ensure that you seal and cover the area thoroughly. There are two ways you can apply the concrete sealer to the surface: a brush or a paint roller.

If you are using a roller to seal the surface, you will still need to use the brush beforehand, because the roller cannot reach the corners. Also, while you seal the surface, make sure that the brush edges do not go dry at any point and blend in with the next stroke. You will need to pay attention because if you do not, it may lead to a visible, uneven patch that will look ugly.

Letting It Dry

It is important that you let the concrete floor dry for at least 24 hours. Read the instructions on the concrete sealer’s package to find out how long you should wait. If it is an area where you drive on, you will need to give it at least three days to seal completely.

While sealing the stamped concrete may seem like a pretty straightforward procedure, there are some common mistakes that you should avoid.

Common Mistakes to Avoid

- 1Never apply the stamped concrete sealer on the surface unless and until it is totally clean .

- 2If you are going to apply a second coat, make sure the first coat is dry. Applying a fresh coat to a wet surface will stir it up and create bulges and indents.

- 3If you are applying a sealant with an anti-skid solution, you will need to keep stirring it. If you do not do this, it may cause the two to separate.

- 4Avoid applying the sealant with a spray gun. Not only will it clog the sprayer nozzle, it will not be able to deliver the anti-skid material as well.

- 5Do not seal when it is raining or when the weather is too humid. The ideal temperature to apply a concrete sealant is below 55 degrees.

- 6Do not let any pets venture over into the area where the sealer is drying. The sealer may react with pet urine, which is very acidic in nature, and may lose its strength.

- 7Avoid dragging sharp objects on your stamped concrete surface. Doing so may scratch the seal off.

Conclusion

Regular upkeep of your stamped concrete paths, patios and will not only help maintain the look but also add value to your property. You can put these extra layers on your stamped concrete now to save on repairs later. Adding anti-skid to the sealer is a good idea because it will prevent the floor concrete from being too slippery when wet.

Remember that stamped concrete can take a lot of abuse but it can be tough to repair if it is chipped or broken. If you follow the advice and the procedure in this article, you can enjoy the craftsmanship of your stamped concrete for many years to come.