If you have a commercial, residential or industrial setting and you have had a newly installed concrete floor, you have probably been told to seal it off. What these contractors do not tell you is why, how, or what to use when it comes to sealing the concrete. You need to seal concrete floors to protect your concrete from water, daily wear and tear, and harsh chemicals. Exposure to these conditions could lead to mildew and mold and could pose a threat to the foundation of your construction.

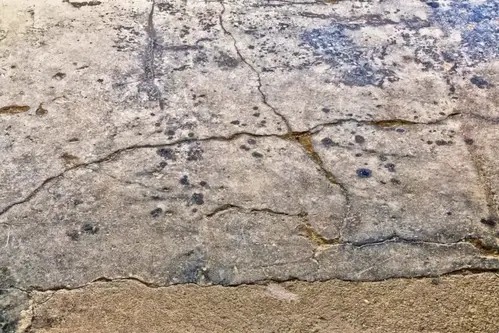

The plus side to having a concrete floor is that they are durable and easy to clean. However, a concrete floor is also vulnerable to contaminants and spills. No matter how hard the surface is, it is bound to crack with time. This is a major concern especially if you have stained or decorative flooring. You need to do what you can to maintain the pristine condition of your concrete floor.

When you do research on how to seal concrete floors, you are likely to be confused by the jargon and process and may be deceived by claims of great performance. This is bound to happen when you are looking for a general sealant for your concrete floor. If you are aiming to find the best sealer for concrete floors, then you do not need to go any further: simply read our comprehensive guide, which also tells you the types of products there are on the market. But if you are looking for an in-depth guide on the what, how, or why of concrete floor sealing, read on.

Table of Contents

- Is Floor Sealer and Floor Paint the Same?

- Is it Necessary to Seal your Concrete Floor?

- Does It Make Changes to the Appearance?

- When Should You Apply the Sealer?

- Will Applying Concrete Sealer Make Your Floor Slippery?

- How Long Will the Concrete Sealer Last?

- What If I Have Cracks in the Concrete Floor?

- Are Concrete Floor Sealers Environment-Friendly?

- DIY: Can I Do Concrete Sealing By Myself?

- Conclusion

Is Floor Sealer and Floor Paint the Same?

Let us get this off the table first — concrete floor sealers are used to seal and bind the surface, whereas floor paints are available in a whole spectrum of sheens. Also, floor sealers can just be left like that or can be painted over. There are plenty of concrete floor sealants, like the Quikrete Acrylic Concrete Cure Seal, which leaves a lovely stain like finish which is not too glossy.

Is it Necessary to Seal your Concrete Floor?

Knowing how to seal concrete floors is a must. If you have a concrete floor, chances are that your contractor told you about the benefits of sealed concrete. Concrete is a porous material that has a tendency to absorb liquids. Sealing concrete floors will not only enhance its look and feel but also protect your concrete floor from hazards such as spilling, erosion, or damage caused by high traffic.

On unsealed concrete, freezing climates can cause the frozen liquids to expand and cause damage that will need filling. Other stuff that can damage the floor would be salt, oil, chemicals, or fertilizers. So, by sealing the concrete (or waxing it in some cases), you are creating a barrier between the concrete and these other elements, thereby protecting the concrete.

Does It Make Changes to the Appearance?

Sealing the concrete floor may or may not change the appearance, depending on the type of concrete sealant. You will hardly be able to tell that there is a concrete sealer if you use a chemically reactive sealer because it is absorbed in the floor. If you use an epoxy or a solvent-based concrete sealer, it will give your concrete floor a wet, high-gloss appearance, making the colors look a lot more enhanced. If you use a water-based acrylic sealer, the colors on your floor will look moderately enhanced and glossy.

There are sealers known as urethanes, which are generally applied over epoxies as a topcoat, and are available in gloss or matte (for a less shiny surface). Some concrete floor sealants may even be colored with tints or opaque shades.

When Should You Apply the Sealer?

Again, this depends on the kind of sealer you are using on your concrete floor. There are high-performance coatings, such as urethanes and epoxies, which should only be applied after the concrete has cured completely (usually, this could take between 25 and 30 days). There are other types of products which are reactive (penetrative) that should be applied as soon as the concrete can take the weight of the installers. These are known as silicates and siliconates. But, as a general thumb rule, nearly all sealers can be applied after the concrete floor has cured.

Will Applying Concrete Sealer Make Your Floor Slippery?

When a concrete sealer is applied to the concrete floor, it will usually be slippery initially while it is wet – just like any other wet surface. But again, it depends on the kind of sealant you are using. A water-based sealer will be less slippery when compared with a solvent-based sealer. So, for these, there are traction additives that can be used with such sealers, and you can ask your local hardware seller for recommendations. These additives are very essential, especially in areas that see a lot of foot or vehicular traffic.

How Long Will the Concrete Sealer Last?

There are some factors at play here – mostly the environment. The period is usually 10 years or so, in the case of reactive chemical sealers, which will last as long as the substrate surface. And depending on the traffic in the area, urethane or epoxy will behave in a similar manner (a wide range of 5 to 10 years). Acrylic resin sealers do a great job of enhancing the look of your concrete floor, such as the Black Diamond Stoneworks Stone Sealer, but they seem to have the shortest lifespans and generally last 1 to 3 years at best.

Other factors that may influence the life span of a concrete sealer are:

What If I Have Cracks in the Concrete Floor?

Well, in this case, you will need to repair these cracks before you apply a concrete sealer. If left vulnerable, the concrete sealer cannot protect the concrete floor from further damage if it has been cracked because of too much sun, water, or chemical exposure. You should also be aware that small cracks can develop into big ones if left untreated, under the right pressure.

For these purposes, a product such as the one-size-fits-all Quikrete Concrete Crack Seal Natural has been proven to be durable and effective.

Are Concrete Floor Sealers Environment-Friendly?

Generally speaking, water-based floor sealers are more environment-friendly than their solvent-based counterparts because the latter may contain dangerous levels of volatile organic compounds (VOCs). These VOCs vaporize under ordinary circumstances indoors and are essentially air contaminants; inhaling them can be dangerous. If you are environmentally conscious, you may need to ask the resellers in your area for recommendations and you might want to know more about the regulations in your state regarding VOCs.

DIY: Can I Do Concrete Sealing By Myself?

While you could pay a company or contractor to do it for you, DIY is what this guide is all about. This guide helps you seal a leaky basement or garage floor, eliminate and control dust buildup from your concrete floor, protect it from spills, abrasions, discoloration, and stains.

Below you'll find some tips to get you started:

- 1Clear the Room - Before you start, you will have to clear the room of all the equipment and put them elsewhere because you will need the area to be free from clutter. While you are doing that, keep in mind that this process is time-consuming and might take a while. So, it is better to store your items or furniture elsewhere for the time being.

- 2Wipe the Floor Clean – The next step is cleaning the area thoroughly. You will need to clean all the trash and dirt from the floor to avoid sealing in dirt and debris with your concrete. Vacuum all the dirt away; you can alternatively use a leaf blower for this purpose.

- 3Scrub, Scrub, and Scrub - The next step is to scrub off all the visible splotches and remove paint or stains that you can see. You will need a scrubbing brush, pre-paint cleaners, and a roll of paper towels to soak up the excess liquid. You need to do the scrubbing and cleaning thoroughly so the sealer will stick to the concrete properly. Also, before using any cleaning product, make sure you read the instructions carefully.

- 4Prepare the Concrete Floor - Pour some of the concrete sealer on the floor and rub it on the surface using your scrubber. Cover the area gradually if you have a large floor, and you can do this by working in small areas one at a time.

- 5Rinse It Off - Once you have covered the entire floor with the cleaner, use a power hose or a power washer to rinse it all. Rinse the sealer off the concrete floor completely. Start from the corner facing the door, and work your way out. If the room has an incline, make sure you are starting from the top and working your way down.

- 6Wait 24 Hours - For the next step, you will have to make sure that the area is completely dry. You may leave a fan on in this area or use a blower. Alternatively, leaving the door open will also speed up the process.

- 7Applying the Concrete Sealer - By now, we are assuming that you already chose the right sealant for your concrete floor and have read the instructions on the package carefully. Make sure that you are applying the sealer at the appropriate temperature because the concrete sealer will not set properly if they are applied in too humid, too hot, or too cold weather. Also, ventilate the room well; open all the windows and switch on any fans that it might have.

- 8Break the Room down in “Parts” - For your own reference, divide the room into four parts for your convenience. This will let you know exactly how much work you have done and how much work you still have to do.

- 9Start “Painting” - You will literally need a paintbrush and there are brushes available on the market for just this purpose. You will need the brush because sometimes, a roller will not be able to do the corners of your concrete floor well. Dip your brush in the concrete sealer and make firm, but even strokes along the edges.

- 10Use a Paint Pad or a Rolling Brush - Pour the concrete sealer in a painting tray and roll the brush or the pad in it evenly, and start painting in long, even strokes. Keep adding the sealer to the brush as required and make sure that the edges do not go dry at any point of this operation. This is to make sure that these edges will blend in the next stroke. Keeping a dry edge will leave a visible, uneven patch.

- 11Apply Evenly - Complete one part of the room as you move along, applying pressure on the brush evenly. Do not let the concrete sealer puddle on the floor at any given point. Puddles will make ugly “scars” on your concrete floor and will stand out.

- 12Let It Be - If you have read the instructions carefully, you will know how long it would take for the concrete sealer to dry out completely. Every sealant will have different instructions, but as a general rule, you should let it dry for at least 24 hours before you walk on it, and 3 more days if it is an area where you drive on.

- 13Is a Second Coat Required? - Some concrete sealers need more than one coat, while others do not. Read the instructions on the packaging. In any case, you may need to wait as long as a week for the first coat to set in before you apply a second coat. Do not start putting on a second coat before that because it would be pointless.

Conclusion

So, there you have it! You now know the entire procedure to seal a concrete floor. Sealing both interior and exterior concrete floors not only adds an extra layer of protection but also saves you money on home repairs and renovations later on. So, make sure you select a professional grade and quality sealer. You can go right ahead and read these reviews to pick up the best one for you.